PIPE FITTINGS & VALVES

- Stainless Steel Valves

-

Cast Iron Valves

- Butterfly Valve

-

Gate Valve

- DIN 3352 F4/F5 Resilient Seated Flanged Gate Valves

- DIN3352 F4 Metal-seal Flanged End Gate Valve

- BS5150 Non-rising Stem Flanged End Gate Valve

- BS5163 Resilient Seated Flanged Gate Valve

- BS3464 Non-rising Stem Gate Valves

- MSS SP-70 Metal-Seal Cast iron Non-Rising Stem Gate Valve

- MSS SP-70 Metal-Seal Cast iron Rising Stem Gate Valve

- AWWA C509 AWWA C515 Cast iron Gate Valve

- Socket End Gate Valve for PVC pipe

- Globe Valve

- Check Valve & Y Strainer

- Fire Protection Valves

-

Pipe Fittings

-

Forged Pipe Fittings

- Socket Weld Union

- Socket Weld Lateral

- Socket Weld Cross

- Socket Weld Half Coupling

- Socket Weld Coupling

- Socket Weld Cap

- Socket Weld Tee

- Socket Weld 90 Degree Elbow

- Socket Weld 45 Degree Elbow

- Socket Weld Reducing Insert

- Socket Weld x Female Threaded Union

- Butt Weld Union

- Threaded 45 Degree Elbow

- Threaded 90 Degree Elbow

- Threaded Street Elbow

- Threaded Tee

- Threaded Cap

- Threaded Adapter

- Threaded Cross

- Threaded Lateral

- Flush Bushing

- Hexagon Head Bushing

- Threaded Coupling

- Threaded Half Coupling

- Hexagon Head Plug

- Round Head Plug

- Square Head Plug

- Threaded Union

- Male x Female Threaded Union

- Lug Nut Union

- Swage Nipple and Bull Plugs

- Butt Weld Outlet

- Elbow Outlet

- Flanged Nipple Outlet

- Lateral Outlet

- Nipple Outlet

- Socket Weld Outlet

- Sweep Outlet

- Threaded Outlet

- Pipe Nipple And Coupling

- Ductile Iron Grooved Pipe Fitting

-

Pipe Clamp Fittings

- G101 Short Tee

- G101 Reducing Short Tee

- G104 Long Tee

- G116 3 Way Through

- G116A-D Add-on 3 Way Through

- G119 2 Socket Cross

- G119A-D Add on 2 Socket Cross

- G123 Variable Elbow 40 °- 70°

- G124 Variable Elbow 15° - 60°

- G125 2 Way 90° Elbow

- G125H Variable Elbow

- G126 Angle Cross 30° - 45°

- G127 Angle Tee 30° - 45°

- G128 3 Way 90° Elbow

- G129 Adjustable Tee 30° - 60°

- G130 Adjustable Corss 30° - 45°

- G131 Base Flange

- G132 Railing Base Flange

- G133 Plastic End Cap

- G134 Ground Socket

- G135 Clamp on Tee

- G136 Add on Tee

- G137 Crossover 90°

- G138 Gate Eye

- G140 Gate Hinge

- G143 Handrail Bracket

-

Forged Pipe Fittings

- Stainless Steel Pipe Fittings

Specification:

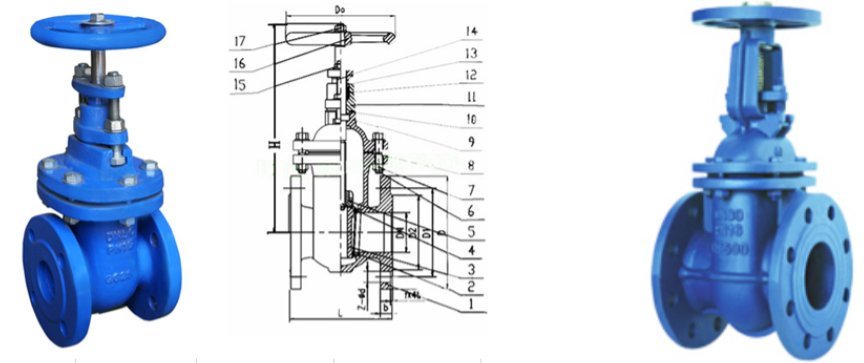

Parts and Materials of Metal Seated Gate Valve - Rising Stem:

| No. | Parts | Cast Iron Material | Ductile Iron Material |  |

| 1 | Body | Cast iron GJL250 | Ductile iron GJS500 | |

| 2 | Body seat ring | Cast brass | Cast brass | |

| 3 | Wedge | Cast iron GJL250 | Ductile iron GJS500 | |

| 4 | Wedge seat ring | Cast brass | Cast brass | |

| 5 | Stem | Stainless steel X20Cr13 | Stainless steel X20Cr13 | |

| 6 | Bolt | Steel grade 8.8 | Steel grade 8.8 | |

| 7 | Nut | Steel grade 8.8 | Steel grade 8.8 | |

| 8 | Bonnet gasket | Graphite | Graphite | |

| 9 | Bonnet | Cast iron GJL250 | Ductile iron GJS500 | |

| 10 | Packing | Graphite | Graphite | |

| 11 | Gland follower | Ductile iron GJS500 | Ductile iron GJS500 | |

| 12 | Nut | Steel grade 8.8 | Steel grade 8.8 | |

| 13 | Bolt | Steel grade 8.8 | Steel grade 8.8 | |

| 14 | Stem nut | Cast brass | Cast brass | |

| 15 | Handwheel | Cast iron GJL250 | Cast iron GJL250 | |

| 16 | Nut | Ductile iron GJS500 | Ductile iron GJS500 |

Dimensions (mm) of DIN3352 F4 Metal-seal Flanged End Gate Valve:

PN10

| DN | L | D | D1 | D2 | b | f | n-d | D0 | H |

| 40 | 140 | 150 | 110 | 84 | 18 | 3 | 4-19 | 160 | 245 |

| 50 | 150 | 165 | 125 | 99 | 20 | 3 | 4-19 | 160 | 255 |

| 65 | 170 | 185 | 145 | 118 | 20 | 3 | 4-19 | 160 | 295 |

| 80 | 180 | 200 | 160 | 132 | 22 | 3 | 8-19 | 160 | 330 |

| 100 | 190 | 220 | 180 | 156 | 24 | 3 | 8-19 | 200 | 385 |

| 125 | 200 | 250 | 210 | 184 | 26 | 3 | 8-19 | 200 | 458 |

| 150 | 210 | 285 | 240 | 211 | 26 | 3 | 8-23 | 250 | 545 |

| 200 | 230 | 340 | 295 | 266 | 26 | 3 | 8-23 | 250 | 683 |

| 250 | 250 | 395 | 355 | 319 | 28 | 3 | 12-23 | 320 | 823 |

| 300 | 270 | 445 | 400 | 370 | 28 | 4 | 12-23 | 320 | 952 |

`

PN16

| DN | L | D | D1 | D2 | b | f | n-d | D0 | H |

| 40 | 140 | 150 | 110 | 80 | 16 | 2 | 4-19 | 160 | 245 |

| 50 | 150 | 165 | 125 | 102 | 16 | 2 | 4-19 | 160 | 255 |

| 65 | 170 | 185 | 145 | 124 | 16 | 2 | 4-19 | 160 | 295 |

| 80 | 180 | 200 | 160 | 140 | 17 | 2 | 8-19 | 160 | 330 |

| 100 | 190 | 220 | 180 | 158 | 17 | 2 | 8-19 | 200 | 385 |

| 125 | 200 | 250 | 210 | 188 | 18 | 3 | 8-19 | 200 | 458 |

| 150 | 210 | 285 | 240 | 212 | 20 | 3 | 8-23 | 250 | 545 |

| 200 | 230 | 340 | 295 | 268 | 21 | 3 | 12-23 | 250 | 683 |

| 250 | 250 | 405 | 355 | 320 | 23 | 3 | 12-28 | 320 | 823 |

| 300 | 270 | 460 | 410 | 378 | 24 | 4 | 12-28 | 320 | 952 |

Product Details

DIN3352 F4 Metal-seal Flanged End Gate Valve

Technical Specifications of DIN3352 F4 Metal-seal Flanged End Gate Valve:

- Design and manufacture: EN1171, EN1074-1 and 2

- Face to face dimension: EN 558-1 Series 14 (DIN3202 F4)

- Flange dimensions and drilling: EN1092-2 PN10/16

- Size range: DN40 - DN300

- Max. working pressure: 1.0/1.6 Mpa

- Inspection test: EN12266

- Working temperature: ≤ 120°C

- Suitable medium: water, oil and gas.

Technical Specifications of DIN3352 F4 Metal-seal Flanged End Gate Valve:

- Design and manufacture: EN1171, EN1074-1 and 2

- Face to face dimension: EN 558-1 Series 14 (DIN3202 F4)

- Flange dimensions and drilling: EN1092-2 PN10/16

- Size range: DN40 - DN300

- Max. working pressure: 1.0/1.6 Mpa

- Inspection test: EN12266

- Working temperature: ≤ 120°C

- Suitable medium: water, oil and gas.

inquire now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.