Butterfly Valve

- Stainless Steel Valves

-

Cast Iron Valves

- Butterfly Valve

-

Gate Valve

- DIN 3352 F4/F5 Resilient Seated Flanged Gate Valves

- DIN3352 F4 Metal-seal Flanged End Gate Valve

- BS5150 Non-rising Stem Flanged End Gate Valve

- BS5163 Resilient Seated Flanged Gate Valve

- BS3464 Non-rising Stem Gate Valves

- MSS SP-70 Metal-Seal Cast iron Non-Rising Stem Gate Valve

- MSS SP-70 Metal-Seal Cast iron Rising Stem Gate Valve

- AWWA C509 AWWA C515 Cast iron Gate Valve

- Socket End Gate Valve for PVC pipe

- Globe Valve

- Check Valve & Y Strainer

- Fire Protection Valves

-

Pipe Fittings

-

Forged Pipe Fittings

- Socket Weld Union

- Socket Weld Lateral

- Socket Weld Cross

- Socket Weld Half Coupling

- Socket Weld Coupling

- Socket Weld Cap

- Socket Weld Tee

- Socket Weld 90 Degree Elbow

- Socket Weld 45 Degree Elbow

- Socket Weld Reducing Insert

- Socket Weld x Female Threaded Union

- Butt Weld Union

- Threaded 45 Degree Elbow

- Threaded 90 Degree Elbow

- Threaded Street Elbow

- Threaded Tee

- Threaded Cap

- Threaded Adapter

- Threaded Cross

- Threaded Lateral

- Flush Bushing

- Hexagon Head Bushing

- Threaded Coupling

- Threaded Half Coupling

- Hexagon Head Plug

- Round Head Plug

- Square Head Plug

- Threaded Union

- Male x Female Threaded Union

- Lug Nut Union

- Swage Nipple and Bull Plugs

- Butt Weld Outlet

- Elbow Outlet

- Flanged Nipple Outlet

- Lateral Outlet

- Nipple Outlet

- Socket Weld Outlet

- Sweep Outlet

- Threaded Outlet

- Pipe Nipple And Coupling

- Ductile Iron Grooved Pipe Fitting

-

Pipe Clamp Fittings

- G101 Short Tee

- G101 Reducing Short Tee

- G104 Long Tee

- G116 3 Way Through

- G116A-D Add-on 3 Way Through

- G119 2 Socket Cross

- G119A-D Add on 2 Socket Cross

- G123 Variable Elbow 40 °- 70°

- G124 Variable Elbow 15° - 60°

- G125 2 Way 90° Elbow

- G125H Variable Elbow

- G126 Angle Cross 30° - 45°

- G127 Angle Tee 30° - 45°

- G128 3 Way 90° Elbow

- G129 Adjustable Tee 30° - 60°

- G130 Adjustable Corss 30° - 45°

- G131 Base Flange

- G132 Railing Base Flange

- G133 Plastic End Cap

- G134 Ground Socket

- G135 Clamp on Tee

- G136 Add on Tee

- G137 Crossover 90°

- G138 Gate Eye

- G140 Gate Hinge

- G143 Handrail Bracket

-

Forged Pipe Fittings

- Stainless Steel Pipe Fittings

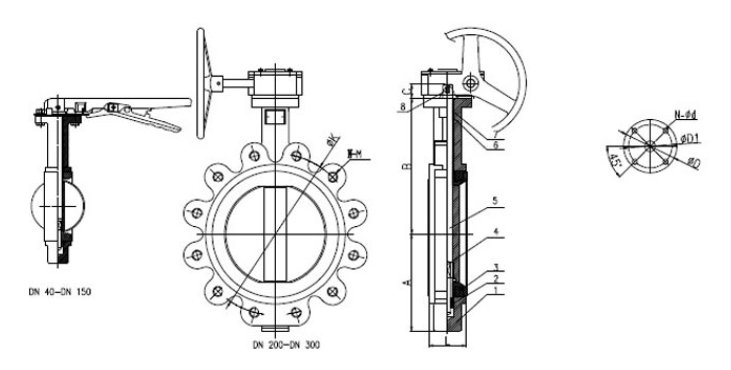

Lug Type Butterfly Valve

Application:

A lug type butterfly valve is a type of butterfly valve that has threaded lugs on the valve body for easy installation and removal from a pipeline. It is also known for its ease of installation and low cost compared to other types of valves.

Specification:

| Size Range | 2~24"(DN50~DN600) |

| Pressure | PN10, PN16, Class150 |

| Seat Materials | NBR, EPDM, VITON, PTFE |

| Disc Materials | Ductile Iron, WCB, CF8,CF8M, Al-bronze C958 |

| Stem Materials | SS304, SS316 |

| End Connection | Wafer |

| Operate | Manual, Worm gear, Pneumatic, Electric-Motorized Disc type: With-pin |

Product Details

In several common connection ways of butterfly valves, the price of wafer type is the cheapest, followed by lug type butterfly valve, flange type butterfly valve is the most expensive, the price is proportional to the overall weight.

In the relevant standard, it is not clear whether the pressure hole of the lug type is a through hole or a threaded hole, so both on the market can be seen.

1. For through hole lug type butterfly valve,it is installed in the same way as the wafer type butterfly valve, so its stability is not as good as flange type one.

2. For threaded hole lug type butterfly valve, its installation way is different with the wafer type and the flange type, at this time the lug type butterfly valve’s holes are like nuts ,when connecting with the pipe flange, the bolts passes through the flange, the holes of the lug type butterfly valve are tightened directly with the bolts.

This installation is stable ,even better than flange types.The lug type body has one integral flange with an identical hole pattern to the pipe flanges. Each hole is tapped from opposite direction, meeting in the center of the hole. This style allows the body to be placed between two flanges. A stud bolt can be inserted through the piping flange and threaded into the integral flange with a nut to secure the entire flange connection.The lug style designs are mainly used in thermal expansion applications in which the risks of straight-through bolting can't be taken while small size designs can't permit two integral flanges.

Features

vertical center line disc

Anti-Blow Out Stem

Bi-Directional

Fire safe Design

Low Friction Body Seat

Zero Leakage

Standard Test

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

Application

1.Water Treatment Plant

2.Breweries

3.Drilling Rigs

4. Heating & Air Conditioning

5.Paper Industry

6.Chemical Industry

7.Gas Plant

8.Pneumatic Conveyors

9.Sugar Industry

10.Waste Effluent Treatment Plant

11.Cooling Water Circulation

12.Compressed Air

inquire now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.