Stainless Steel Pipe Fittings

- Stainless Steel Valves

-

Cast Iron Valves

- Butterfly Valve

-

Gate Valve

- DIN 3352 F4/F5 Resilient Seated Flanged Gate Valves

- DIN3352 F4 Metal-seal Flanged End Gate Valve

- BS5150 Non-rising Stem Flanged End Gate Valve

- BS5163 Resilient Seated Flanged Gate Valve

- BS3464 Non-rising Stem Gate Valves

- MSS SP-70 Metal-Seal Cast iron Non-Rising Stem Gate Valve

- MSS SP-70 Metal-Seal Cast iron Rising Stem Gate Valve

- AWWA C509 AWWA C515 Cast iron Gate Valve

- Socket End Gate Valve for PVC pipe

- Globe Valve

- Check Valve & Y Strainer

- Fire Protection Valves

-

Pipe Fittings

-

Forged Pipe Fittings

- Socket Weld Union

- Socket Weld Lateral

- Socket Weld Cross

- Socket Weld Half Coupling

- Socket Weld Coupling

- Socket Weld Cap

- Socket Weld Tee

- Socket Weld 90 Degree Elbow

- Socket Weld 45 Degree Elbow

- Socket Weld Reducing Insert

- Socket Weld x Female Threaded Union

- Butt Weld Union

- Threaded 45 Degree Elbow

- Threaded 90 Degree Elbow

- Threaded Street Elbow

- Threaded Tee

- Threaded Cap

- Threaded Adapter

- Threaded Cross

- Threaded Lateral

- Flush Bushing

- Hexagon Head Bushing

- Threaded Coupling

- Threaded Half Coupling

- Hexagon Head Plug

- Round Head Plug

- Square Head Plug

- Threaded Union

- Male x Female Threaded Union

- Lug Nut Union

- Swage Nipple and Bull Plugs

- Butt Weld Outlet

- Elbow Outlet

- Flanged Nipple Outlet

- Lateral Outlet

- Nipple Outlet

- Socket Weld Outlet

- Sweep Outlet

- Threaded Outlet

- Pipe Nipple And Coupling

- Ductile Iron Grooved Pipe Fitting

-

Pipe Clamp Fittings

- G101 Short Tee

- G101 Reducing Short Tee

- G104 Long Tee

- G116 3 Way Through

- G116A-D Add-on 3 Way Through

- G119 2 Socket Cross

- G119A-D Add on 2 Socket Cross

- G123 Variable Elbow 40 °- 70°

- G124 Variable Elbow 15° - 60°

- G125 2 Way 90° Elbow

- G125H Variable Elbow

- G126 Angle Cross 30° - 45°

- G127 Angle Tee 30° - 45°

- G128 3 Way 90° Elbow

- G129 Adjustable Tee 30° - 60°

- G130 Adjustable Corss 30° - 45°

- G131 Base Flange

- G132 Railing Base Flange

- G133 Plastic End Cap

- G134 Ground Socket

- G135 Clamp on Tee

- G136 Add on Tee

- G137 Crossover 90°

- G138 Gate Eye

- G140 Gate Hinge

- G143 Handrail Bracket

-

Forged Pipe Fittings

- Stainless Steel Pipe Fittings

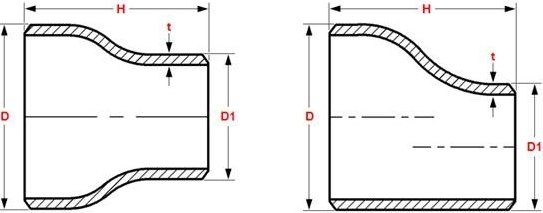

Butt Welding SS Eccentric / Concentric Reducer

Application:

Size: 1/2"-80"/DN15-DN2000

Material: Stainless Steel

Standard: ASME/ANSI B16.9, B16.11, B16.28, JIS B2311, B2312, B2312, B2316 ASTM A403 MSS SP-43, SP-83, SP-97

Type: Seam Or Seamless

End: beveled end

Surface: Black Paint/Rust-proof Oil/Hot Dipped Galvanized

Wall Thickness: SCH10/10S, SCH20/20S, STD, SCH40/40S, XS, SCH80,SCH100, SCH120, SCH140, SCH160, XXS etc.(for ANSI),SGP(for JIS)

Connection: Welding

Specification:

ASME B16.9: Pipe Reducers

Dimensions of Recucers

| NPS | OD at Bevel | End-to- End, H | |

| Large End, D | Small End,D1 | ||

| 3/4×1/2 | 26.7 | 21.3 | 38 |

| 3/4x3/8 | 17.3 | ||

| 1×3/4 | 33.4 | 26.7 | 51 |

| 1×1/2 | 21.3 | ||

| 1-1/4×1 | 42.2 | 33.4 | 51 |

| 1-1/4×3/4 | 26.7 | ||

| 1-1/4×1/2 | 21.3 | ||

| 1-1/2×1-1/4 | 48.3 | 42.2 | 64 |

| 1-1/2×1 | 33.4 | ||

| 1-1/2×3/4 | 26.7 | ||

| 1-1/2×1/2 | 21.3 | ||

| 2×1-1/2 | 60.3 | 48.3 | 76 |

| 2×1-1/4 | 42.2 | ||

| 2×1 | 33.4 | ||

| 2×3/4 | 26.7 | ||

| 2-1/2×2 | 73 | 60.3 | 89 |

| 2-1/2×1-1/2 | 48.3 | ||

| 2-1/2×1-1/4 | 42.2 | ||

| 2-1/2×1 | 33.4 | ||

| 3×2-1/2 | 88.9 | 73 | 89 |

| 3×2 | 60.3 | ||

| 3×1-1/2 | 48.3 | ||

| 3×1-1/4 | 42.2 | ||

| 3-1/2×3 | 101.6 | 88.9 | 102 |

| 3-1/2×2-1/2 | 73 | ||

| 3-1/2×2 | 60.3 | ||

| 3-1/2×1-1/2 | 48.3 | ||

| 3-1/2×1-1/4 | 42.2 | ||

| 4×3-1/2 | 114.3 | 101.6 | 102 |

| 4×3 | 88.9 | ||

| 4×2-1/2 | 73 | ||

| 4×2 | 60.3 | ||

| 4×1-1/2 | 48.3 | ||

| 5×4 | 141.3 | 114.3 | 127 |

| 5×3-1/2 | 101.6 | ||

| 5×3 | 88.9 | ||

| 5×2-1/2 | 73 | ||

| 5×2 | 60.3 | ||

| 6×5 | 168.3 | 141.3 | 140 |

| 6×4 | 114.3 | ||

| 6×3-1/2 | 101.6 | ||

| 6×3 | 88.9 | ||

| 6×2-1/2 | 73 | ||

| 8×6 | 219.1 | 168.3 | 152 |

| 8×5 | 141.3 | ||

| 8×4 | 114.3 | ||

| 8×3-1/2 | 101.6 | ||

| 10×8 | 273 | 219.1 | 178 |

| 10×6 | 168.3 | ||

| 10×5 | 141.3 | ||

| 10×4 | 114.3 | ||

| 12×10 | 323.8 | 273 | 203 |

| 12×8 | 219.1 | ||

| 12×6 | 168.3 | ||

| 12×5 | 141.3 | ||

| 14×12 | 355.6 | 323 | 330 |

| 14×10 | 273 | ||

| 14×8 | 219.1 | ||

| 14×6 | 168.3 | ||

| 16×14 | 406.4 | 355.6 | 356 |

| 16×12 | 323.8 | ||

| 16×10 | 273 | ||

| 16×8 | 219.1 | ||

| 18×16 | 457.2 | 406.4 | 381 |

| 18×14 | 355.6 | ||

| 18×12 | 323.8 | ||

| 18×10 | 273 | ||

| 20×18 | 508 | 457.2 | 508 |

| 20×16 | 406.4 | ||

| 20×14 | 355.6 | ||

| 20×12 | 323.8 | ||

| 22×20 | 558.8 | 508 | 508 |

| 22×18 | 457.2 | ||

| 22×16 | 406.4 | ||

| 22×14 | 355.6 | ||

| 24×22 | 609.6 | 558.8 | 508 |

| 24×20 | 508 | ||

| 24×18 | 457.2 | ||

| 24×16 | 406.4 | ||

| 26×24 | 660 | 610 | 610 |

| 26×22 | 559 | ||

| 26×20 | 508 | ||

| 26×18 | 457 | ||

| 28×26 | 711 | 660 | 610 |

| 28×24 | 610 | ||

| 28×20 | 508 | ||

| 28×18 | 457 | ||

| 30×28 | 762 | 711 | 610 |

| 30×26 | 660 | ||

| 30×24 | 610 | ||

| 30×20 | 508 | ||

| 32×30 | 813 | 762 | 610 |

| 32×28 | 711 | ||

| 32×26 | 660 | ||

| 32×24 | 610 | ||

| 34×32 | 864 | 813 | 610 |

| 34×30 | 762 | ||

| 34×26 | 660 | ||

| 342×4 | 610 | ||

| 36×34 | 914 | 864 | 610 |

| 36×32 | 713 | ||

| 36×30 | 762 | ||

| 36×26 | 660 | ||

| 36×24 | 610 | ||

| 38×36 | 965 | 914 | 610 |

| 38×34 | 864 | ||

| 38×32 | 813 | ||

| 38×30 | 762 | ||

| 38×28 | 711 | ||

| 38×26 | 660 | ||

| 40×38 | 965 | 610 | |

| 40×36 | 1016 | 914 | |

| 40×34 | 864 | ||

| 40×32 | 813 | ||

| 40×30 | 762 | ||

| 42×40 | 1016 | 610 | |

| 42×38 | 1067 | 965 | |

| 42×36 | 914 | ||

| 42×34 | 864 | ||

| 42×32 | 813 | ||

| 42×30 | 762 | ||

| 44×42 | 1118 | 1067 | 610 |

| 44×40 | 1016 | ||

| 44×38 | 965 | ||

| 44×36 | 914 | ||

| 46×44 | 1168 | 1118 | 711 |

| 46×42 | 1067 | ||

| 46×40 | 1016 | ||

| 46×38 | 965 | ||

| 48×46 | 1219 | 1168 | 711 |

| 48×44 | 1118 | ||

| 48×42 | 1067 | ||

| 48×40 | 1016 | ||

*All dimensions are in mm unit(inch unit data sheet is also available upon request).

Product Details

A reducer is a pipe coupling with a larger bore size at one end and a smaller bore size at the other end.It is used to change the flow rate in pipeline.Base on connection ways,there are 3 types of reducers :threaded reducer ,grooved reducer and butt welding reducer.

Generally ,the butt welded reducer is made from pipes.Put a fixed length steel pipe on a conical mould,and its shape is changed by pressing down.Reducing one end or extend one end,then a welded reducer is formed.For big size reducers or low pressure welded reducers,they are made from steel coils.Rolling up the steel plate to a reducer shape,and welding them together.

What is the difference between a concentric and eccentric reducer?

The Concentric reducer two ends are centered in a line,while the Eccentric reducer have the offset center of both ends and has an edge that is parallel to the pipe.Concentric pipe reducer is used when the pipe is vertical andeccentric reducer is ofen used when the pipes are lay on a pipe rack,because of the parallel edge,it could allow the reducer and pipe next to the walls or groud with out taking up space.

Size: 1/2"-80"/DN15-DN2000

Technical: Forged and pushing

Material: Carbon Steel, Stainless Steel, Alloy Steel

Carbon Steel:ASTM, A234WPB, A234WPC, A420WPL6, Q235,10#, A3, Q235A, 20G, 16Mn, DIN St37, St45.8, St52.4, St.35.8, St.35.8.

Stainless Steel:1Cr18Ni9Ti 0Cr18Ni9 00Cr19Ni10 0Cr17Ni12Mo2Ti,00Cr17Ni14Mo2 304 304L 316 316L

Alloy Steel:16Mn Cr5Mo 12Cr1MoV 10CrMo910 15CrMo 12Cr2Mo1,A335P22 St45.8, ASTM A860 WPHY X42 X52 X60 X70

Standard: ASME/ANSI B16.9, B16.11, B16.28, JIS B2311, B2312, B2312, B2316 ASTM A403 MSS SP-43, SP-83, SP-97

Model: 45°/ 90°/180 LR/SR Elbow, Reducers, Tee, Bends, Cap, Cross.

Type: Seam Or Seamless

End: beveled end

Surface: Black Paint/Rust-proof Oil/Hot Dipped Galvanized

Wall Thickness: SCH10/10S, SCH20/20S, STD, SCH40/40S, XS, SCH80,SCH100, SCH120, SCH140, SCH160, XXS etc.(for ANSI),SGP(for JIS)

Elbow Angles: 30/45/60/90/180°

Connection: Welding

Shape:Equal, Reducing

Certificate: ISO -9001:2000, API, CCS

Application:Petrochemical & Gas industry, Power industry, Valve industry, Water works, Shipbuilding industry, Construction etc

Packing: Plywood Pallets/ Wooden Case Or As Per your Specification

MOQ: to be negotiated.

Sample: Available

Service: Customized OEM

Pakage: wooden case & pallet

Payment term: T/T or L/C

Delivery:7-30days according to order quantity.

inquire now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.