Stainless Steel Pipe Fittings

- Stainless Steel Valves

-

Cast Iron Valves

- Butterfly Valve

-

Gate Valve

- DIN 3352 F4/F5 Resilient Seated Flanged Gate Valves

- DIN3352 F4 Metal-seal Flanged End Gate Valve

- BS5150 Non-rising Stem Flanged End Gate Valve

- BS5163 Resilient Seated Flanged Gate Valve

- BS3464 Non-rising Stem Gate Valves

- MSS SP-70 Metal-Seal Cast iron Non-Rising Stem Gate Valve

- MSS SP-70 Metal-Seal Cast iron Rising Stem Gate Valve

- AWWA C509 AWWA C515 Cast iron Gate Valve

- Socket End Gate Valve for PVC pipe

- Globe Valve

- Check Valve & Y Strainer

- Fire Protection Valves

-

Pipe Fittings

-

Forged Pipe Fittings

- Socket Weld Union

- Socket Weld Lateral

- Socket Weld Cross

- Socket Weld Half Coupling

- Socket Weld Coupling

- Socket Weld Cap

- Socket Weld Tee

- Socket Weld 90 Degree Elbow

- Socket Weld 45 Degree Elbow

- Socket Weld Reducing Insert

- Socket Weld x Female Threaded Union

- Butt Weld Union

- Threaded 45 Degree Elbow

- Threaded 90 Degree Elbow

- Threaded Street Elbow

- Threaded Tee

- Threaded Cap

- Threaded Adapter

- Threaded Cross

- Threaded Lateral

- Flush Bushing

- Hexagon Head Bushing

- Threaded Coupling

- Threaded Half Coupling

- Hexagon Head Plug

- Round Head Plug

- Square Head Plug

- Threaded Union

- Male x Female Threaded Union

- Lug Nut Union

- Swage Nipple and Bull Plugs

- Butt Weld Outlet

- Elbow Outlet

- Flanged Nipple Outlet

- Lateral Outlet

- Nipple Outlet

- Socket Weld Outlet

- Sweep Outlet

- Threaded Outlet

- Pipe Nipple And Coupling

- Ductile Iron Grooved Pipe Fitting

-

Pipe Clamp Fittings

- G101 Short Tee

- G101 Reducing Short Tee

- G104 Long Tee

- G116 3 Way Through

- G116A-D Add-on 3 Way Through

- G119 2 Socket Cross

- G119A-D Add on 2 Socket Cross

- G123 Variable Elbow 40 °- 70°

- G124 Variable Elbow 15° - 60°

- G125 2 Way 90° Elbow

- G125H Variable Elbow

- G126 Angle Cross 30° - 45°

- G127 Angle Tee 30° - 45°

- G128 3 Way 90° Elbow

- G129 Adjustable Tee 30° - 60°

- G130 Adjustable Corss 30° - 45°

- G131 Base Flange

- G132 Railing Base Flange

- G133 Plastic End Cap

- G134 Ground Socket

- G135 Clamp on Tee

- G136 Add on Tee

- G137 Crossover 90°

- G138 Gate Eye

- G140 Gate Hinge

- G143 Handrail Bracket

-

Forged Pipe Fittings

- Stainless Steel Pipe Fittings

Stainless Steel Spectacle Blind Flange

Application:

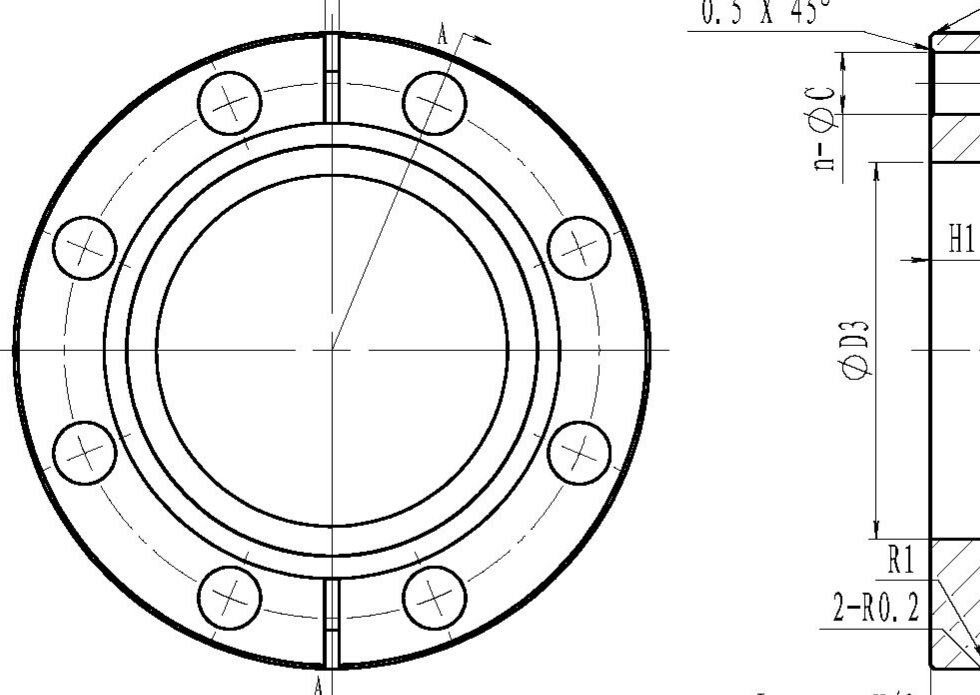

"Spectacle Blind Flange" is a type of flange used in piping systems, particularly in industries such as oil and gas, chemical processing, and petrochemicals. This specialized flange consists of two metal discs connected by a central section or handle. One of the discs has an opening or hole, while the other is solid. By aligning the handle with either the opening or the solid portion, the flow of fluid through the pipeline can be controlled.

Specification:

PRODUCT NAME | Stainless Steel Spectacle Blind Flange |

SAMPLE SUPPORT | Yes |

DELIVERY TIME | Depends on Quantity and Other Requirements |

MOQ | 200kg / Depends on Flange Size |

PRICE | The Higher The Quantity, The Cheaper |

SIZE | 1/2"-60"(DN10-DN1500) |

MATERIAL | Carbon steel / ASTM Alloy Steel / Stainless steel |

THICKNESS | View Flange Catalog |

PRESSURE RATING | View Flange Catalog |

SEALING SURFACE | FF, RF, MFM, TG, FF |

SURFACE TREATMENT | Anti-rust oil / Raw. |

CERTIFICATION | ISO9001:2000 , API, CE, According to Requirements |

Product Details

Types of Line Blinds

Line Blinds come in three basic forms: Spectacle Blinds, Figure-8, and Paddle Blinds. These devices are used to isolate or 'turn off' portions of piping systems. Line blinds can be used together with a valve or instead of a valve. In the image on the right, we see an installed Spectacle Blind in the 'open' position.

Line Blinds come in three basic forms: Spectacle Blinds, Figure-8, and Paddle Blinds. These devices are used to isolate or 'turn off' portions of piping systems. Line blinds can be used together with a valve or instead of a valve. In the image on the right, we see an installed Spectacle Blind in the 'open' position.

The name "spectacle blind flange" is derived from its appearance, resembling the shape of the eyeglasses frame "spectacles" when viewed from the side, with the handle resembling the bridge of the glasses. This flange plays a crucial role in ensuring the efficient and safe operation of piping systems in various industrial settings.The spectacle blind is sometimes sold split into it’s two parts, the line blank, and the ring spacer.

Line Blanks:The solid side of the spectacle blind can be referred to as a line blank, skillet blind, paddle blank, paddle blind, or spade. It forms a positive shut-off when used alone or as half of a spectacle blind. The line is a 'wafer style' device, designed to fit inside the bolt hole circle. A flange spreader is shown on the right being used to prepare a pair of flanges to accept a line blank and two gaskets. To maintain the spacing of the flanges when the line is open, a ring spacer is used.

Benefits of EATHU Forge

EATHU is a professional flange forging factory in China for thirty years., dedicated to producing and supplying high-quality flange products. Our continuous technological innovation and quality management have earned us a good reputation and customer base. We have three flange production lines and one stainless steel flange production line, which can meet the flange needs of different materials and specifications.

EATHU forging factory possesses advanced production equipment, such as CNC lathes, CNC machining centers, and forging equipment.

We have a professional technical team that ensures stable product quality and efficient production.

Our focus on technological innovation and process improvement allows us to continuously enhance product performance and reliability.

We have a comprehensive quality control system and testing equipment to ensure strict monitoring and inspection of every aspect of the production process.

Our product line includes various types of flanges, such as Flat Welding Flange, Butt Welding Flange, Socket Welding Flange, Threaded Flange, and more. These flanges are widely used in industries such as petroleum, chemical, electric power, and shipbuilding. Our flange products comply with international standards, such as ANSI, ASME, API, DIN, BS, and JIS. We can also customize and produce flanges according to customers’ special requirements. Our experienced production team can customize flange products to meet various specifications and materials according to customer needs. We strictly implement a quality management system to ensure that each batch of products undergoes rigorous inspection and testing, resulting in stable and reliable product quality.

|  |  |

QC Center

China flange manufacturer EATHU, maintains strict quality control and product testing to ensure the quality of its flanges. The company has established a comprehensive quality management system to achieve the highest level of quality control for each production process. Due to our strict implementation, we have obtained ISO9001 certification.

China flange manufacturer EATHU, maintains strict quality control and product testing to ensure the quality of its flanges. The company has established a comprehensive quality management system to achieve the highest level of quality control for each production process. Due to our strict implementation, we have obtained ISO9001 certification.

We accept any third party inspection specified by our customers, such as TUV, DNV, BV, SGS, IEI, SAI, etc. All goods are inspected before packing and shipping.

EATHU's quality control process is well established and detailed.

Customized Solutions

EATHU attaches importance to customer's demand and try to meet customer's demand, we support flange customization and other products customization, EATHU has its own forging factory, can make customized metal parts according to drawings, so that not only can meet customer's requirements for products, but also can avoid material waste and reduce the cost of both sides.

If you need to customize special shape flanges, you can send your drawings, our engineers will give you a quote!

inquire now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.